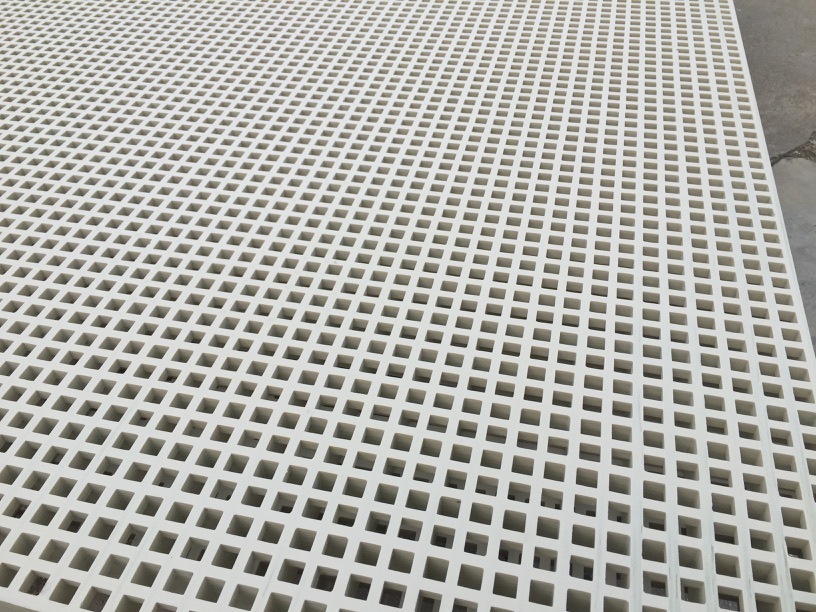

Welded grating is a highly versatile and durable material that has a wide range of applications in various industries, including construction, manufacturing, and telecommunications. It is a type of steel grating that is created by joining heavy-duty flat bars with perpendicular crossbars at a high temperature to form a rigid, sturdy, and anti-slip surface.

In this article, we will explore the benefits, applications, and installation process of welded grating to help you understand how this remarkable material can improve your operations and enhance safety in your workplace.

Benefits of Welded Grating

1. Durability: Welded grating is made of robust materials that can withstand heavy loads, extreme weather, chemicals, and corrosion. It is ideal for outdoor environments and industrial applications that require long-term resistance to wear and tear.

2. Anti-slip surface: Welded grating has a serrated surface that provides excellent traction and prevents slips and falls. This feature is highly beneficial in wet or oily conditions, reducing the risk of accidents and injuries.

3. Customization: Welded grating is available in various sizes, shapes, and configurations, making it easy to adapt to different applications and environments. It can be manufactured to meet specific requirements, such as load-bearing capacity, span, and spacing.

4. Low maintenance: Welded grating requires minimal maintenance and is easy to clean. It does not rust, deform, or corrode, reducing the need for frequent repairs and replacements.

Applications of Welded Grating

1. Flooring: Welded grating is commonly used as a flooring material in industrial plants, processing facilities, and other heavy-duty environments that require high durability, anti-slip properties, and easy maintenance. It is suitable for walkways, platforms, mezzanines, ramps, and stair treads.

2. Drainage: Welded grating is an excellent material for drainage systems, such as trench covers, catch basins, and sumps. The open design of the grating allows water, mud, and debris to flow through, preventing clogs and flooding.

3. Safety barriers: Welded grating is a popular choice for safety barriers and fencing in construction sites and industrial facilities. Its rugged construction provides robust protection against accidental impacts and intrusions while allowing air and light to flow freely.

4. Architectural features: Welded grating can be used for decorative purposes in modern architecture and landscaping. It can create stunning visual effects, such as sun screens, façade panels, and pergolas.

Installation of Welded Grating

Installing welded grating requires careful planning, preparation, and execution to ensure maximum safety and performance. Here are the essential steps in the installation process:

1. Measure and mark the installation area, taking into account the load-bearing capacity, span, and spacing requirements.

2. Clean and level the surface to ensure proper alignment and stability.

3. Secure the base plates or clips to the underlying structure using bolts, anchors, or welding.

4. Lay the welded grating panels in place, ensuring proper alignment and spacing between the bars and crossbars.

5. Secure the grating panels to the base plates or clips using the appropriate clamps or fixtures.

6. Inspect the installation for any defects, gaps, or misalignments, and make the necessary adjustments.

Conclusion

Welded grating is a versatile and cost-effective material that delivers excellent performance and safety benefits in various industrial applications. Its durability, anti-slip properties, customization options, and easy installation make it a popular choice for flooring, drainage, safety barriers, and architectural features. By understanding the benefits, applications, and installation process of welded grating, you can make informed decisions and select the ideal solutions for your operational needs.